Active pore as a pump for micro- and nanofluids

Simulations and calculations show that even a simple tube coated with a catalyst can transmit a signal in a fluid without the need of any electrical component or moving parts. The pores can also be used as mixers or pumps in microscopic devices. The findings are relevant to emerging technologies in micro- and nanofluidics, with applications in the chemical, medical and biotechnology industries.

Scientific result

In their paper published in the scientific journal Physical Review Letters, the scientists demonstrate that a pore equipped with a catalyst can be used as a micro- or nanopump for fluids. The catalyst leads to the formation of a chemical substance that interacts with the pore wall, causing pressure differences to transport the fluid. This transport can either be a steady pumping or a pulsating flow with tunable frequency. The results were obtained in close collaboration between HI ERN scientists Goncalo Antunes, Dr. Paolo Malgaretti and Prof. Jens Harting, as well as Prof. Siegfried Dietrich from the Max Planck Institute for Intelligent Systems in Stuttgart.

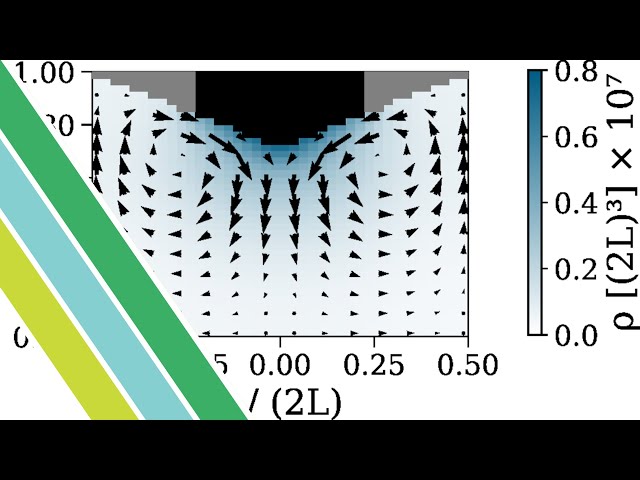

Video shows signal transmission at very high Péclet number: The fluid cannot relax to a steady state and a pulsating flow develops, with sustained oscillations in the flow rate. Top video shows a longitudinal cross-section, and the bottom video shows a transversal cross-section. The pulsing also breaks the radial symmetry of the pore, increasing the mixing.

Social and scientific relevance

The emerging technologies of micro- and nanofluidics are already being successfully applied to the synthesis of microparticles as well as the transport of biomaterials and the functioning of chemical reactors. The techniques are being used in biomedical research to study and manipulate biological tissue and to develop new drugs and delivery methods. Approaches based on them, such as lab-on-a-chip and organ-on-chip, are poised to fundamentally change drug testing and disease diagnosis and treatment. Other applications such as 3D printing also require fluids to be pumped through micrometer-scale channels.

In all of these situations, fluids must be transported in a controlled manner at the smallest scales. Controlling chemical reactions also requires solutions to be stirred using micromixers, making micromixers and pumps basic components of many microfluidic systems.

Further details

The smaller the cross-sections of the channels, the more relevant surface and finite size effects become, which can be exploited for designed microfluidic applications. From this perspective, the phoretic phenomena studied here can provide an intriguing technique to manipulate fluid flows in micro- or nano-channels and pores.

These behaviors are expected to occur for pores with sizes ranging from 100 to 1000 micrometers. The effect even occurs when the pore is left-right symmetric. This pumping is possible due to a spontaneous symmetry breaking. This symmetry breaking always occurs when advection, i.e. a continuous, large-scale flow, rather than diffusion, the chaotic mixing of particles, is the dominant mechanism of solute transport.

Original publication

G. C. Antunes, P. Malgaretti, J. Harting, S. Dietrich

Pumping and Mixing in Active Pores

Phys. Rev. Lett. (25 October 2022), DOI: https://doi.org/10.1103/PhysRevLett.129.188003

Contacts

- Institute of Energy Technologies (IET)

Room 5007

- Institute of Energy Technologies (IET)

Room 5012

- Institute of Energy Technologies (IET)

Room 5011